We employ state-of-the-art automated equipment for cable crimping, encompassing wire cutting, wire stripping, and the crimping process itself. Cable crimping holds a pivotal role in the realms of electronics and electrical engineering, representing the skillful practice of establishing secure and reliable electrical connections by joining wires to connectors, terminals, or other conductive elements. At its core, cable crimping ensures the seamless and safe functioning of electrical circuits.

Cable crimping necessitates the utilization of specialized tools and equipment to compress a connector onto the end of a wire. This connector may take the form of a terminal, lug, pin, or another suitable component. The outcome is a gas-tight connection that not only ensures electrical soundness but also delivers mechanical robustness. In essence, cable crimping yields a steadfast and low-resistance electrical connection, minimizing the risks of wire pullout, electrical arcing, and other potential issues.

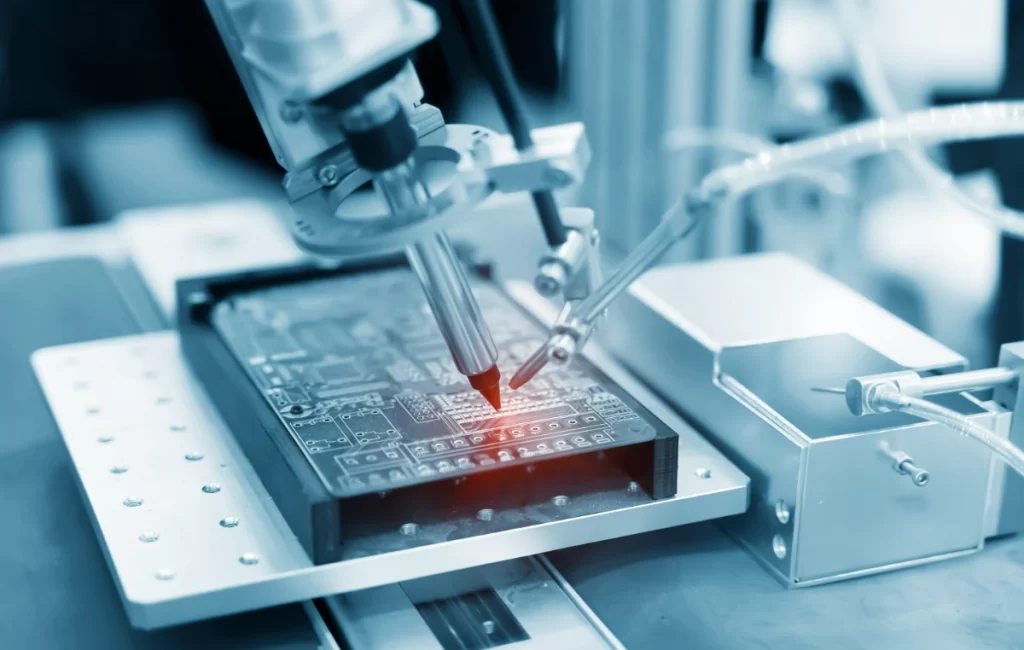

To attain the requisite precision and reliability in cable crimping, the incorporation of automated wire cutting, wire stripping, and wire crimping equipment is crucial. These machines are meticulously designed to execute routine cable processing tasks with exceptional accuracy. Automated wire cutting guarantees that cables are trimmed to the precise length needed, while wire stripping machines meticulously remove insulation, leaving the conductor intact.

The final stage in the cable crimping process involves specialized machines that affix connectors to the prepared cable ends. These machines provide an unparalleled level of accuracy and consistency that is challenging to achieve manually. They apply uniform pressure to establish a gas-tight connection, ensuring both electrical and mechanical integrity.

In industries where reliability and safety are of paramount importance, such as aerospace, automotive, and telecommunications, cable crimping stands as a standard and critical practice. It serves as a crucial step in guaran