- Reduce the impact of temperature on PCB board stress.

Since temperature is the main source of board stress, you can reduce the occurrence of board bending and warping by lowering the temperature of the reflow oven or slowing down the heating and cooling speed of the board in the reflow oven.

- Use high Tg plates.

High Tg sheets have a high glass transition temperature, which can increase the rigidity and heat resistance of the PCB board and reduce the risk of deformation during the reflow soldering process.

- Increase the thickness of the circuit board.

If the thickness of the PCB board is insufficient, it will be easily deformed during the reflow soldering process. If there is no requirement for thinness and lightness, the thickness of the PCB board can be increased to 1.6mm, which can greatly reduce the risk of board bending and deformation.

- Reduce the size of the circuit board and reduce the number of panels.

Larger circuit boards will dent and deform in the reflow oven due to their own weight. Therefore, try to put the long side of the circuit board as the board edge on the chain of the reflow oven, and reduce the number of panels to reduce the dent deformation caused by the weight of the circuit board itself.

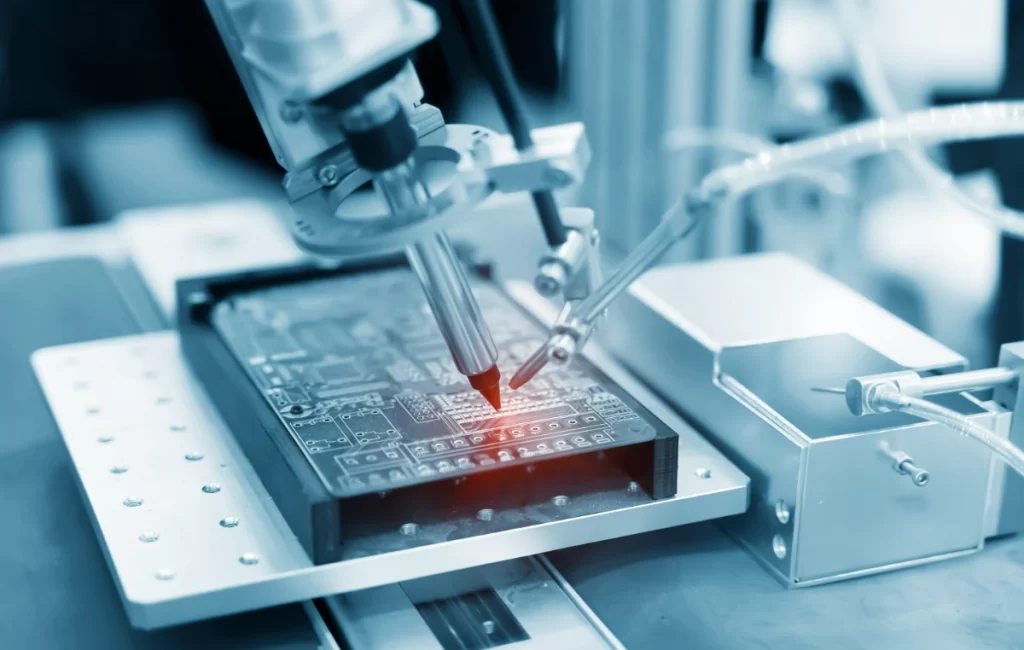

- Use oven tray jig.

The oven tray can hold the circuit board in place. When the temperature of the circuit board drops below the Tg value and begins to harden again, the original size can be maintained, thereby reducing the risk of board bending and warping.

In short, avoiding PCB board bending and warping due to reflow soldering requires starting from many aspects, including selecting appropriate materials, optimizing design, adjusting process parameters, etc.

We are a company with 20 years of experience, providing customers with “excellent price, high quality, fast delivery” PCB+SMT one-stop service. Our products are widely used in artificial intelligence, instrumentation, communication equipment, photovoltaic energy storage, and automotive electronics. and other fields. The plates have obtained international certifications such as UL, ISO, CQC, VDE, etc., ensuring product quality reliability and stability.