Quality

IQC&IPQC&OQC

We conduct rigorous inspections for incoming materials, throughout the manufacturing process, and prior to shipment. This ensures that every stage, from raw material procurement to production, and before delivery, meets quality requirements, guaranteeing that the products delivered to customers are 100% compliant.

ESD Control

In PC Electronics, we have ESD prevention measures for every meanufacuring process, and our measures are carefully documented.

ㆍWe train our employees who handle any ESD Sensitive products.

ㆍOur employees undergo a full-body static electricity elimination test before entering the workshop each time.

ㆍGrounding systems; wirst strap connection points, ESD flooring and work surface are measured every three months by the ESD Coordinator and the records are stored.

We use packaging with shielding properties to store and transport ESDS outside the EPA.

Dry Cabinet

Aligned with the IPC/JEDEC J-STD-033 Joint Industry Standard, we store Moisture Sensitive Components (MSDs) in a dry cabinet to prevent malfunctions and enhance production quality.

Environmental Conditions Monitoring

Supervising environmental conditions is crucial during the electronic product manufacturing process to uphold safety and precision.

We employ temperature and humidity monitoring devices to oversee environmental conditions at every stage of the manufacturing process, both in our shop floors and warehouses.

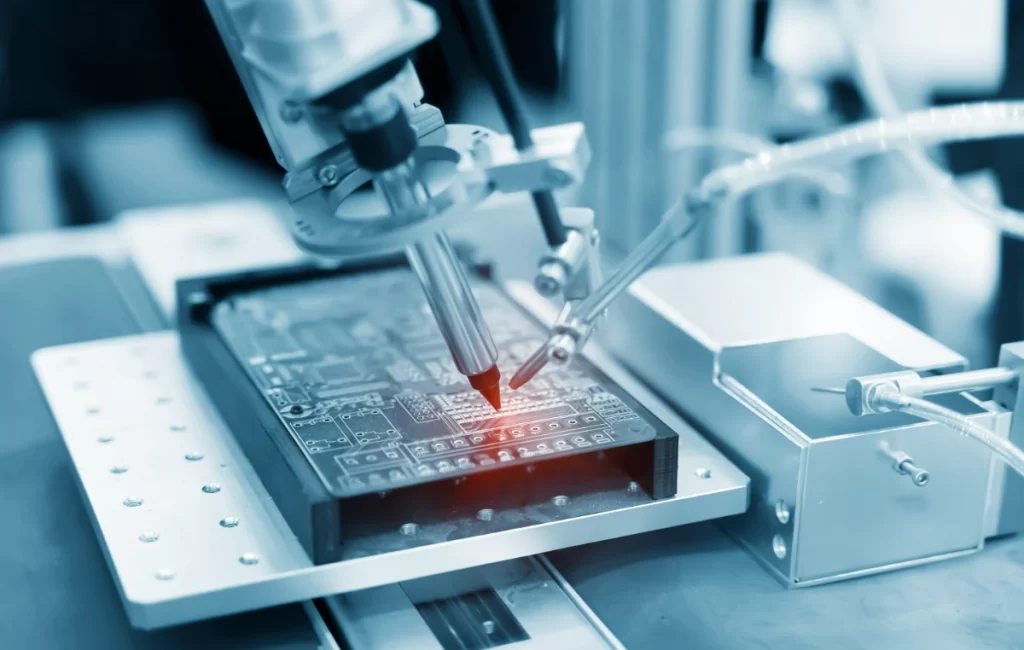

3D Automated Optical Inspection (AOI)

Due to the growing prevalence of microelectronics driven by technological advancements and the increasing intricacy of electronic board designs, Automatic Optical Inspection (AOI) machines have become a vital solution for the surface mount technology (SMT) industry.

Utilizing our 3D AOI machine, we conduct highly precise and reliable control operations during the post-reflow stage of our electronic boards, addressing issues such as excess/insufficient soldering, bridging, missing and lifted components, direction, and offset. Following the inspection process, any No Good (NG) boards are automatically separated, loaded into the magazine, and transferred to the rework station. This inspection ensures the continuity of quality management, detecting errors in the early stages of production and implementing corrective measures.

Our R&D department continuously examines the 3D data obtained from inspection processes to determine the root causes of defects. Necessary corrective and preventive measures are then applied in the designs.

Certificates

Check our certificates to see our proven expertise which requires quality standards, regulatory requirements, industrial and environmental compliances of the markets and geographies we serve.